Enamel is composed of two main materials: metal and clay. The process of making enamel is to coat a layer of porcelain clay on metal objects (such as iron and steel), and then heat and sinter it to firmly bond the porcelain clay to the metal. This forms a layered structure on the enamel surface. The metal provides the structural support of the cup, while the enamel layer brings smoothness, wear resistance, heat preservation, and other properties.

The production process of enamel can be traced back to ancient times, but modern industrial production technology has made enamel a popular product. Enamel cups are usually made of iron or steel as a base material and then coated with an enamel layer. This production method makes enamel cups relatively affordable while also providing high durability and durability.

Therefore, the family enamel cups used in childhood are composed of metal and porcelain clay. The metal provides strength and structure, and the enamel layer makes the cups smooth, wear-resistant, and corrosion-resistant.

>

Home / News / Industry News / What material was the essential enamel for every family when they were young?

Industry News

What material was the essential enamel for every family when they were young?

PREV:The enamel industry ushered in a wave of technological innovation to improve product performance.NEXT:No next article

Related Products

-

151D Round Rim Spill-Resistant Single-Handle Pot Lid Included

View More

151D Round Rim Spill-Resistant Single-Handle Pot Lid Included

View More

-

151D Round Rim Spill-Resistant Single-Handle Enamel Pot Without Lid

View More

151D Round Rim Spill-Resistant Single-Handle Enamel Pot Without Lid

View More

-

151DC Rimmed Spill-Resistant Single-Handle Pot

View More

151DC Rimmed Spill-Resistant Single-Handle Pot

View More

-

156D Enamel Single-Handle Ladle

View More

156D Enamel Single-Handle Ladle

View More

-

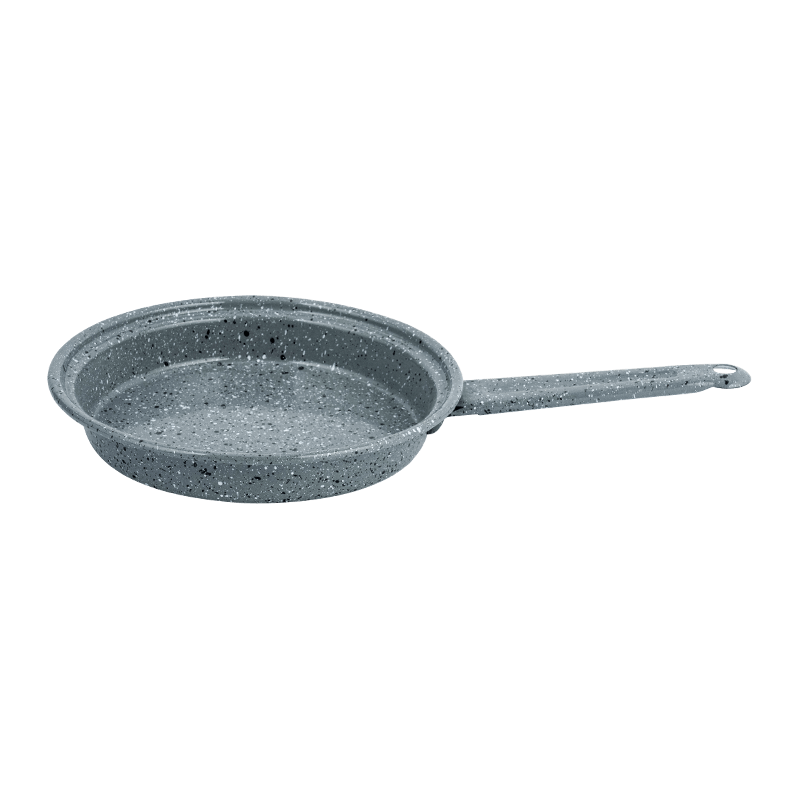

407D Enamel Non-Stick Frying Pan

View More

407D Enamel Non-Stick Frying Pan

View More

-

753D Enamel Flared Rim Spill-Resistant Straight Pot

View More

753D Enamel Flared Rim Spill-Resistant Straight Pot

View More

-

406D Enamel Stainless Steel Round Rim Seafood Stockpot

View More

406D Enamel Stainless Steel Round Rim Seafood Stockpot

View More

-

601DG-3 Handle Enamel Stockpot

View More

601DG-3 Handle Enamel Stockpot

View More

-

673D-5 Color Printed Enamel Stockpot

View More

673D-5 Color Printed Enamel Stockpot

View More

-

810D Enamel Flat-Bottom Stockpot

View More

810D Enamel Flat-Bottom Stockpot

View More

-

768D Enamel Flared Rim Straight Low Stockpot

View More

768D Enamel Flared Rim Straight Low Stockpot

View More

-

801D Enamel Double-Handle Straight Stockpot

View More

801D Enamel Double-Handle Straight Stockpot

View More

Quick Links

Products

Contact Us

- Phone: +86-18868946157

- Tel: +86-0574-62154948

- Email: sandy@hxenamel.com / amy@hxenamel.com

- Add: No.13 West Ruhu Road, Simen Town, Yuyao, Zhejiang, China

Mobile

Copyright 2024 © Yuyao Zhili Metal Products Co., Ltd. Rights Reserved.All Rights Reserved. Wholesale Daily-Use Steel Plate Enamel Products Manufacturer

English

English 中文简体

中文简体